Overview:

Breadboards are great for prototyping circuits, but they aren’t so good for actually using the thing you’re building.

At some point, you’ll probably want to form a project more permanent. the simplest thanks to doing this is to place it on a PCB.

The performance of your circuit will depend greatly on how it’s laid out on the PCB Design.

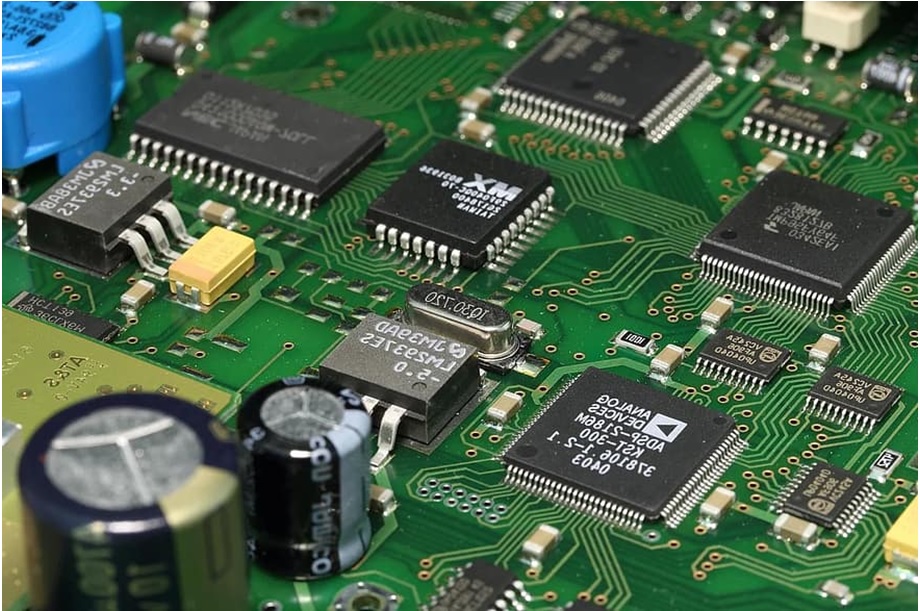

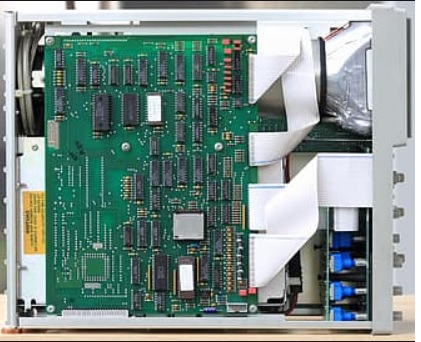

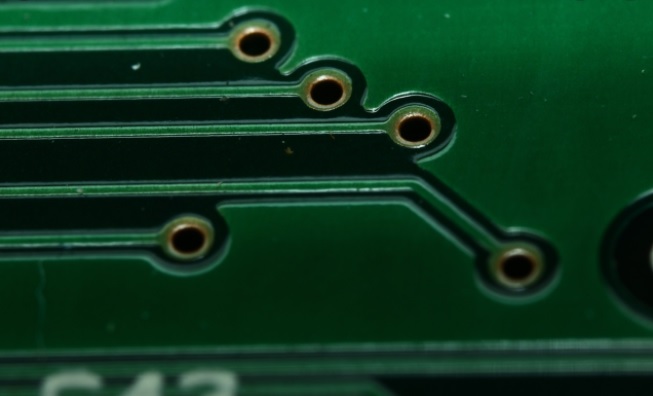

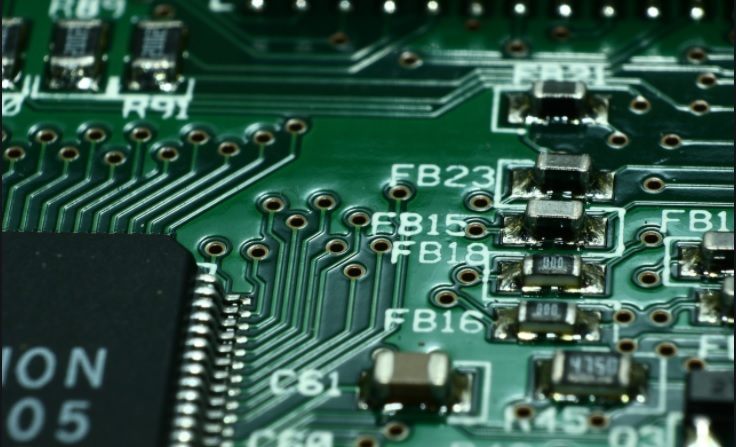

The printed circuit board (PCB) mechanically supports and electrically connects electronic components or components using conductive tracks, pads, and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate.

they’re also utilized in some electrical products, like passive switch boxes.

Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely used. PCBs require additional design effort to get out of the circuit, but manufacturing and assembly are often automated.

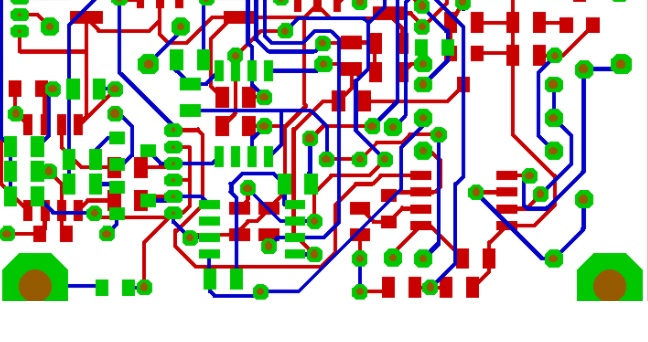

Specialized CAD software is out there to try to too much of the work of layout. Mass-producing circuits with PCBs is cheaper and faster than with other wiring methods, as components are mounted and wired in one operation.

Large numbers of PCBs are often fabricated at an equivalent time, and therefore the layout only has got to be done once. PCBs also can be made manually in small quantities, with reduced benefits.

PCBs are often single-sided (one copper layer), double-sided (two copper layers on each side of 1 substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of the substrate).

Multi-layer PCBs leave much higher component density because circuit traces on the inner layers would otherwise take up surface space between components. the increase in popularity of multilayer PCBs with quite two, and particularly with quite four, copper planes was concurrent with the adoption of surface mount technology. However, multilayer PCBs make the repair, analysis, and field modification of circuits far more difficult and typically impractical.

What is Printed Circuit Board (PCB)?

The printed circuit board (PCB) mechanically supports and electrically connects electronic components or components using conductive tracks, pads, and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate.

Use of Printed Circuit Board (PCB)?

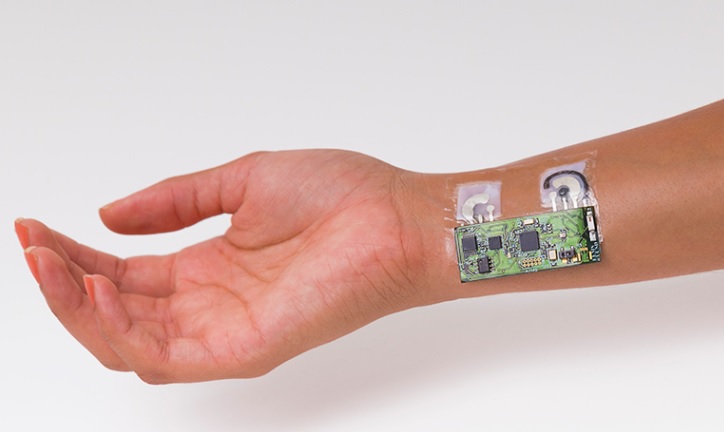

Medical Equipment or Medical Industry

Electronic products are now more sophisticated and less expensive than previous generations, making it easier to explore new and exciting medical technologies. Most medical devices use the most powerful PCB, which is used to create the smallest and most dense design possible. This helps to alleviate some of the unique challenges involved in the development of devices in the medical field due to the need for smaller and heavier sizes. PCBs get access to everything from small devices, such as pacemakers, to very large devices such as X-ray machines or CAT scanners.

Medical PCB applications are growing rapidly as the medical device industry itself. A few common PCB medical applications include the following:

• Monitors: Personal and health care providers include blood glucose testers, heart rate and blood pressure monitors, and more.

• Scanning technology: CT scanners and ultrasonic technology often use PCB-based electronics.

• Control systems: The device that controls the supply of fluid, flow rate, and distribution is controlled electronically.

• Internal devices: Cardiac comforters and similar internal medical devices maintain the patient’s health, driven by small PCBs in their facilities.

• Scientific Equipment: Medical research uses many scientific tools to diagnose and evaluate patient outcomes. These include electric microscopes, photometers, and control systems for generators and compressors, among others.

Consumer Electronics:

Consumer electronics are devices that we use every day, such as smartphones or computers. Even brand new refrigerator models often include electronic components. Inside all these devices is a PCB.

Due to the high volume at which these consumer electronics are manufactured, the number of PCBs produced to control them must be proportional. These high-capacity PCBs have low cost per unit, which keeps the price of the final product very low. The challenge is to maintain the quality of these PCBs, which is why PCB manufacturers must adhere to strict industry standards and quality control measures to ensure that all consumer electronics operations are as expected.

The use of PCBs in consumer electronics is widespread. The following are just some of the common uses for PCBs in consumer electronics:

• Mobile Devices: Smartphones and tablets are at the heart of our daily routine, operating as everything from our alarm clocks to our GPS.

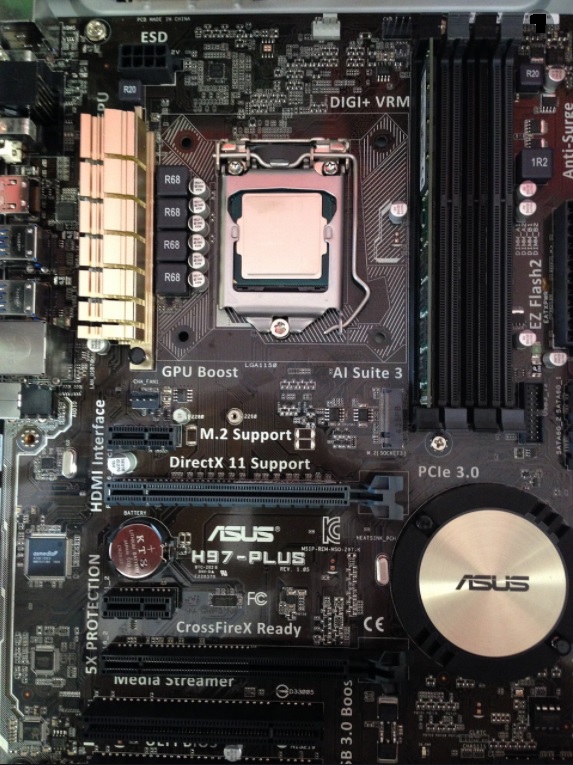

• Computer Electronics: Desktops and laptops both contain PCBs in their cores, as do screens and associated peripheral devices.

• Recording Devices: Camcorders, digital cameras, microphones and other recording devices all rely on their internal PCBs to operate.

• Entertainment Systems: Everything in your home entertainment system, from your DVD player and video game console to your television and stereo set.

• Household appliances: Almost all modern appliances use technology: Alarm clocks, microwaves, refrigerators, coffee makers, etc.

Aerospace Equipment Manufacturing :

Like automotive applications, the use of PCB aerospace requires greater precision and durability. Jets and rockets often go to great lengths to disrupt their space travel, which means that a solid PCB can withstand enough pressure to degrade the process. Around this, many aerospace manufacturers use flexible, lightweight and thin PCBs in addition to resisting vibration damage.

In addition to durability, aerospace PCBs must be highly efficient and accurate, producing good workmanship to avoid technical challenges. Since the electronics used in aerospace technology are critical to the safety of the car and its crew, it is important that it works properly.

A few of the most common Aerospace applications for PCBs include the following:

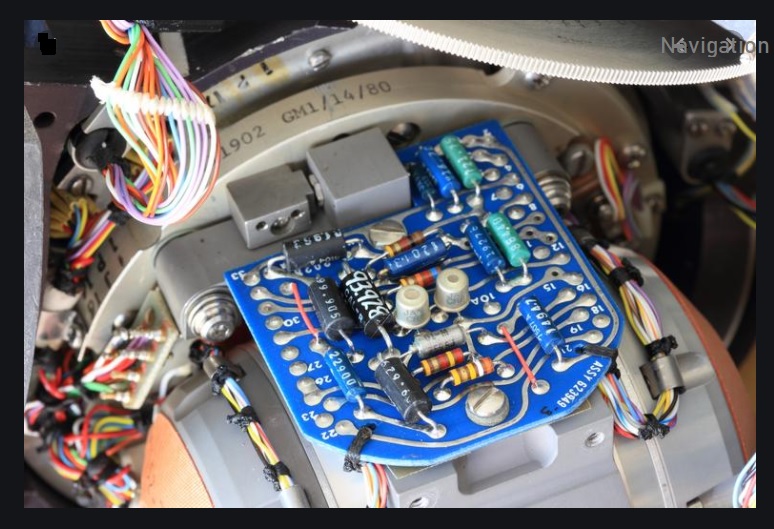

• Monitoring Equipment: Equipment, including accelerometers, pressure sensors, microphones, and torque and forcing sensors all use PCBs as part of their basic function. These products are used within engines and in cabins and rockets, both to monitor vehicle performance and to communicate with ground control.

• Testing Equipment: In addition to aircraft performance, PCBs are involved in the construction and testing of aircraft vehicles. Test machines that collect data during the process of forming, vibrating, and testing aircraft use PCBs in its core. This information can be used to develop more efficient, efficient, and safer aircraft.

Lighting Application:

The LED lighting industry is growing rapidly in response to increased interest in an efficient and inexpensive lighting system, but much of the functionality of LED lights depends on the temperature of its system. In many companies, the solution to this problem lies in aluminum-based PCBs, We call the LED PCB.

To help you understand why the LED lighting industry uses Led PCB, we have explained the nature of PCB base layers, the attractive characteristics of aluminum PCBs, and why they work so well in the LED lighting industry.

LED PCB is now widely used in more and more areas due to Energy Conservation and Environmental Protection.

Automotive Application:

Cars are becoming more and more dependent on electricity in modern times. In the past, electric circuits were used only for headlight switches and wipers, and modern cars use electronics for additional purposes.

Modern cars are taking advantage of continuous circuit technology by installing PCBs in some new systems. PCBs that work with high frequency signals such as RF, microwave, or millimeters of wavelengths commonly used in sensory operating systems are now common in automobiles. In fact, radar technology reintroduced into military vehicles has now become commonplace in modern vehicles to help vehicles avoid collisions, monitor blind spots, and adapt to traffic conditions where the vehicle is under boat control.

These advanced systems bring improved road safety while at the same time providing an improved driving experience, which is why they are so popular in modern cars. Manufacturers of these systems, therefore, must acquire and use an increasing number of high-quality printed circuit boards and associated materials.

What are the different types of Printed Circuit Boards (PCBs):

Printed circuit boards are widely used in various electronics and are often the basis of devices. These circuit boards provide a piece of physical support and also provide a cable connection and surface. Printed circuit boards are usually made of composite materials, such as fiberglass or epoxy composite.

Most circuit boards designed for simple electronics contain only one layer, while high-quality and sophisticated electronics may require circuit boards with two or more layers, depending on the complexity. There are various types of circuit boards that have their own manufacturing facilities, such as the type of material and their use.

To help you understand the different types of printed circuit boards, we have provided additional details below.

Single-sided PCBs:

Single-sided PCBs or single-layer PCBs, in fact, circuit boards consist of only one layer of the substrate or basic material. These boards are simple and inexpensive to produce both in small and large quantities, which is why they are so popular, especially for hobbyists. One side means that circuits and components and components are installed on one side of the board, which means that this type of board is best suited for simple electronics. Although cheaper and faster production, due to its unilateral design, there are limitations to what it can be used for.

Double-Sided PCBs:

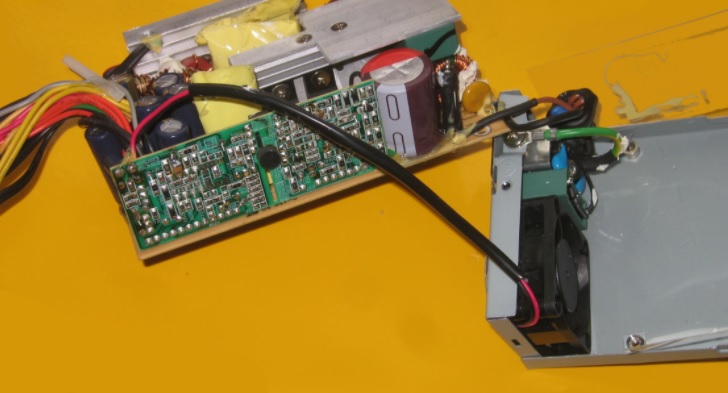

Circular boards printed on both sides are similar to one-sided boards, except that they have floating layers on both sides of the substrate. This is done so that the objects are attached to both sides of the board. On two-sided boards, these parts can be connected in two ways; surface mounts technology or through-hole technology.

The technology that goes through the hole involves drilling holes in the board to feed the small tracks and then attach them to objects by soldering. Surface mount technology is the process of inserting metals directly into the PCB, which allows multiple circuits to be installed in small spaces. The advantages of this technology when compared to the hole-hole, is that it allows the printed circuit board to have a low weight while being able to perform many functions at fast prices.

Multilayer PCBs:

Multi-layer PCBs continue to improve the technology of two-dimensional boards as multi-layer boards can have three or more layers depending on the needs and application. These circuit boards consist of several layers of substrate separated by coating materials. Like double-sided circuit boards, multi-layer boards can also use flow technology or surface inserts to connect components.

The design of the multi-layered circuit board improves the performance of the two-sided board. Typically, these multi-layer PCBs have a space between three to ten layers but can have multiple layers depending on application requirements. These types of PCBs are often used for advanced equipment such as medical equipment and servers.

Rigid PCBs:

Rigid PCBs are made of solid substrate materials that can help reduce bending and flexibility of the board. By making the board stronger and more stable, it can help extend the life of objects as they will be significantly reduced by environmental damage, such as walking and shaking.

A popular application for solid PCBs for computer motherboards. These types of boards are often used for this program because they create low electronic noise. This means that the circuit board is designed to reduce the number of electrical currents running between the elements and to reduce distortion.

Flexible PCBs:

Unlike solid PCBs, flexible PCBs or flexible PCBs, they are printed circuit boards designed to be flexible and easily accessible. These types of boards can come in a variety of forms with single-sided, double-sided, or multi-row sides. The substrate itself is a flexible plastic that allows the printed circuit board to fit in a variety of conditions without damaging the circuits. Flexible PCBs can be more expensive to design and manufacture than solid PCBs, however, they offer a variety of advantages over solid boards. In applications where space and weight are important, a flexible PCB can replace heavy or heavy parts and wires.

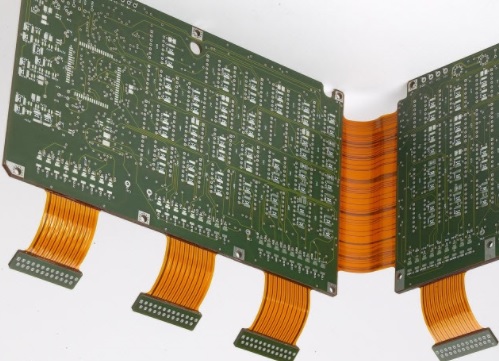

Rigid-Flex PCBs:

Rigid-Flex PCB conditions that combine the technology of solid PCBs with flexible PCBs. In fact, a Rigid-flex board consists of multiple layers of flexible PCBs attached to a number of solid PCB layers. Sturdy circuit boards offer more benefits than using flexible or sturdy boards in a variety of applications.

Rigid-Flex boards usually have parts under your regular flexible or sturdy board as both cords of boards can be combined into one board. By combining these two circuit boards, you can achieve a consistent design that can help reduce the overall board size and weight.