Instrumentation, which suggests usage of measuring instruments to watch and control processes, are some things vital for all the manufacturing and processing plants.

Any device, which measures physical quantities – say flow, temperature, levels, distance, angle, or maybe pressure – is named an instrument. An Instrument that is attached to an impact system could provide signals which are wont to operate valves, regulators, circuit breakers or relays, thus providing remote or automated controls.

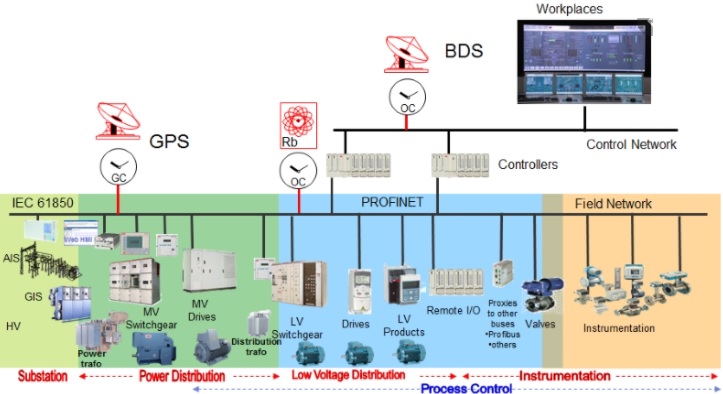

The signals could alternately be used for informational purposes or they might even be connected to a PLC, DCS, SCADA, or the other sort of computer-based controller.

Information could then be interpreted into readable values so as to exercise desired levels of control. Instrumentation training becomes a necessity for plant operators.

The nature of the labor of an instrumentation engineer ranges from designing, developing, installing, managing equipment that is wont to monitor and control machinery.

The discipline of instrumentation engineering branched out of the streams of electrical and electronic engineering a while within the early a part of the 1970s.

Instrumentation engineering specializes in the principle and operation of measuring instruments that are utilized in fields of design, the configuration of automated systems in electrical, pneumatic domains, etc. Instrumentation and Control Engineering may be a vast field.

It primarily deals with automation, field instruments, and final control elements (valves) that measure and control various physical parameters (temperature, pressure, flow and etc.).

Its application is extremely vast including bio-med, chemical, oil & gas, power, and lots of more. The off-beat application of building and airport automation is arising and instrumentation features a huge role in it. Robotics is another interesting field that needs multidisciplinary skills including Instrumentation and Control.