Industrial Automation is a discipline that includes knowledge and expertise from various branches of engineering including electrical, electronics, chemical, mechanical, communications, and more recently computer and software engineering. Automation & Control by its very nature demands a cross-fertilization of these faculties.

Industrial Automation Engineers have always drawn new technologies and implemented original or enhanced versions to meet their requirements. As the range of technology diversifies the demand for the innovative ability of these Engineers has increased.

In industries, control strategies use a group of technologies that are implemented to urge the specified performance or output, making the automation system most essential for industries.

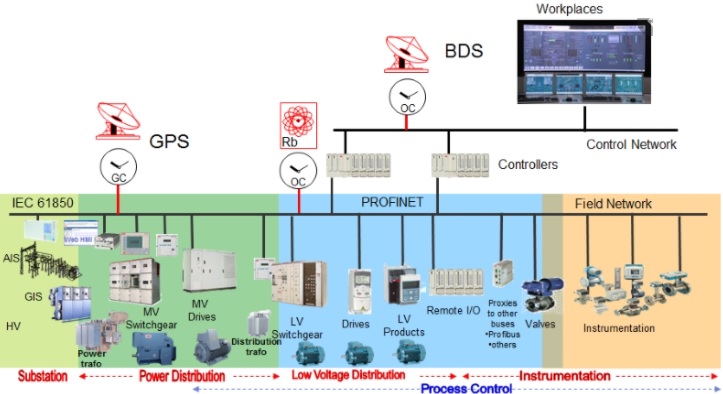

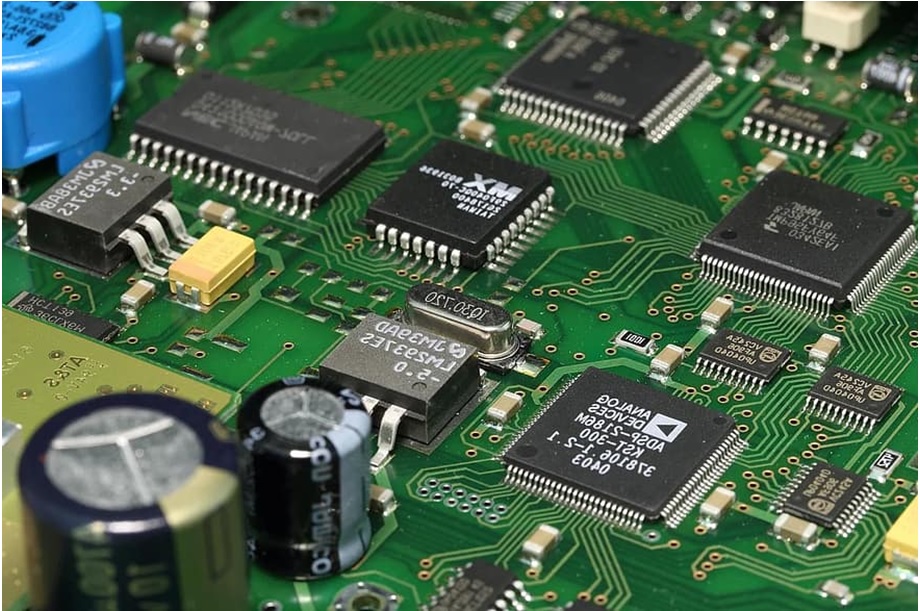

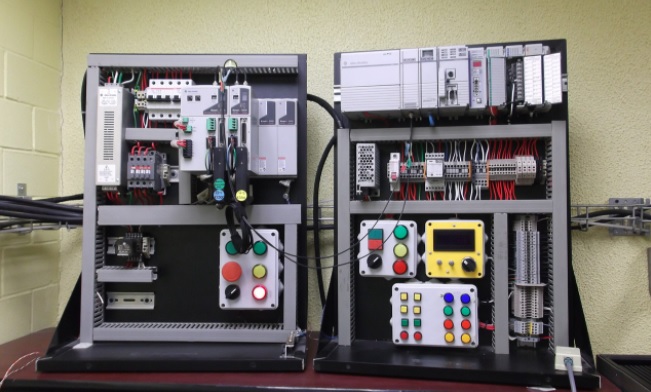

industrial automation involves the usage of advanced control strategies like cascade controls, modern control hardware devices like PLC’s/SCADA/DCS and sensors and other instruments for sensing the control variables, signal conditioning equipment to attach the signals to the control devices, drives, and other significant final control devices, standalone computing systems, communication systems, alarming and HMI (Human Machine Interface) systems.

Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic, and computers, usually together. Complicated systems, like modern factories, airplanes, and ships typically use these combined techniques.

Industrial engineers have envisioned fully automated factories since a minimum of the center of the 20th century, But the important race to automate manufacturing are often said to possess begun within the 1980s when US car manufacturers came up with the vision of “lights-out” manufacturing.

the thought was to beat their rivals by automating the factories to such an extent that the whole manufacturing process might be left to robots. To an excellent extent, it’s remained only a vision thus far.